03-10-2013, 06:28 PM

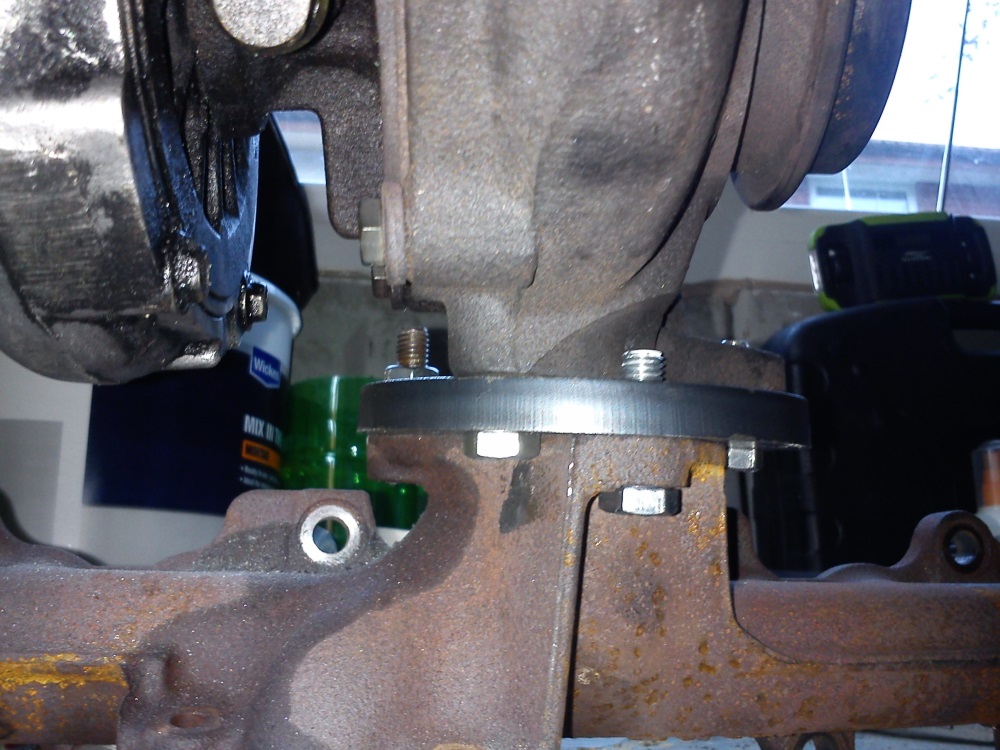

Getting there with the turbo, finished the adaptor plate, the slotted holes for the manifold studs might end up getting slotted further to twist the turbo and bring the cold side away from the water rail at the back of the engine. I should really of test fitted it on the engine before taking it apart.

Took the vacuum actuator off the turbo after measuring its travel (11mm from the stop to fully open). Had to clamp it to the desk to get some of the nuts undone but got the old actuator disassembled and then went through my box of turbo bits and found a boost actuator to play with. Sadly its got 2 boost inlets but tested it using a track pump and its got a good 20mm of movement at full travel but that isn't till about 40psi. It does 11mm at about 15psi which is nearly perfect. The new actuator is alot smaller so I'm considering weather to use the heat shield off the old actuator or keep it off to save space.

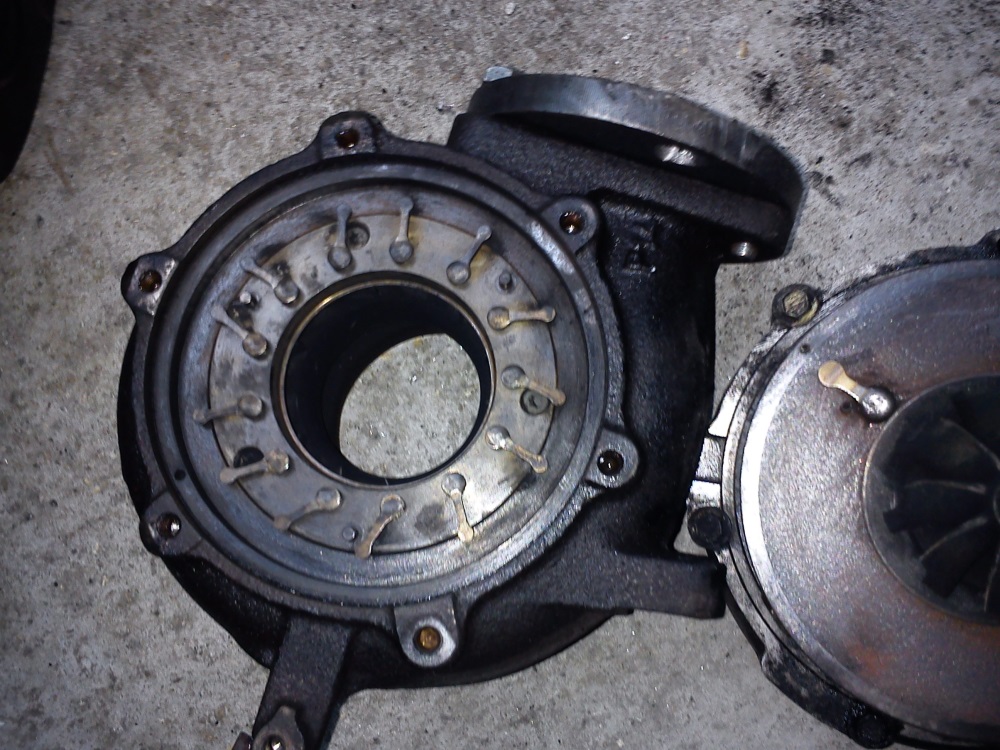

Finally took the turbo apart and cleaned some of the soot out the VNT mechanism. Was well stuck together and when i finally knocked the hot side off the CHRA it dropped to the floor and I nearly lost one of the bushings that the vane control ring rotates on. Anyway had to pull the little locating pin circled but had no luck so ended up filing it flat.

There is 13 flaps in the ring and I wanted to clock it 2 flaps but had to go 3 as otherwise the control lever would drop onto one of the bushings.

Been really grateful for having a tap and die set today, been worth its weight in gold. Cleaned up all the turbo and manifold holes and knocked loads of rust out of them, taped a fresh hole in the adapter and cleaned up the very tight thread on the new actuator.

Took the vacuum actuator off the turbo after measuring its travel (11mm from the stop to fully open). Had to clamp it to the desk to get some of the nuts undone but got the old actuator disassembled and then went through my box of turbo bits and found a boost actuator to play with. Sadly its got 2 boost inlets but tested it using a track pump and its got a good 20mm of movement at full travel but that isn't till about 40psi. It does 11mm at about 15psi which is nearly perfect. The new actuator is alot smaller so I'm considering weather to use the heat shield off the old actuator or keep it off to save space.

Finally took the turbo apart and cleaned some of the soot out the VNT mechanism. Was well stuck together and when i finally knocked the hot side off the CHRA it dropped to the floor and I nearly lost one of the bushings that the vane control ring rotates on. Anyway had to pull the little locating pin circled but had no luck so ended up filing it flat.

There is 13 flaps in the ring and I wanted to clock it 2 flaps but had to go 3 as otherwise the control lever would drop onto one of the bushings.

Been really grateful for having a tap and die set today, been worth its weight in gold. Cleaned up all the turbo and manifold holes and knocked loads of rust out of them, taped a fresh hole in the adapter and cleaned up the very tight thread on the new actuator.