Posts: 20,092

Threads: 591

Joined: Nov 2012

Reputation:

54

Location: Cotswolds

Car Model/Spec: Stage 13 16v HDi

Thanks: 22

Given 68 thank(s) in 68 post(s)

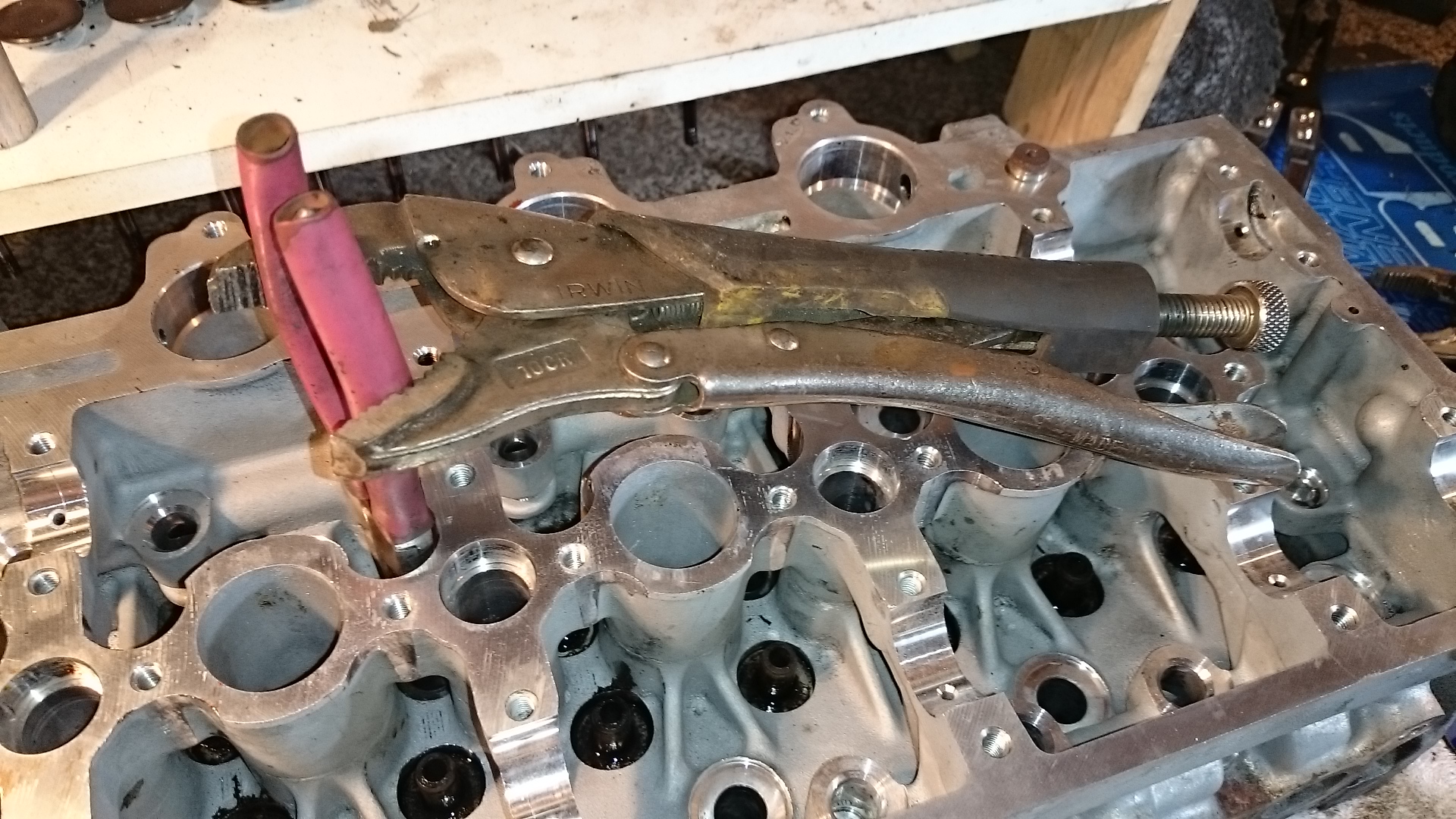

Moved on to sorting the head now...

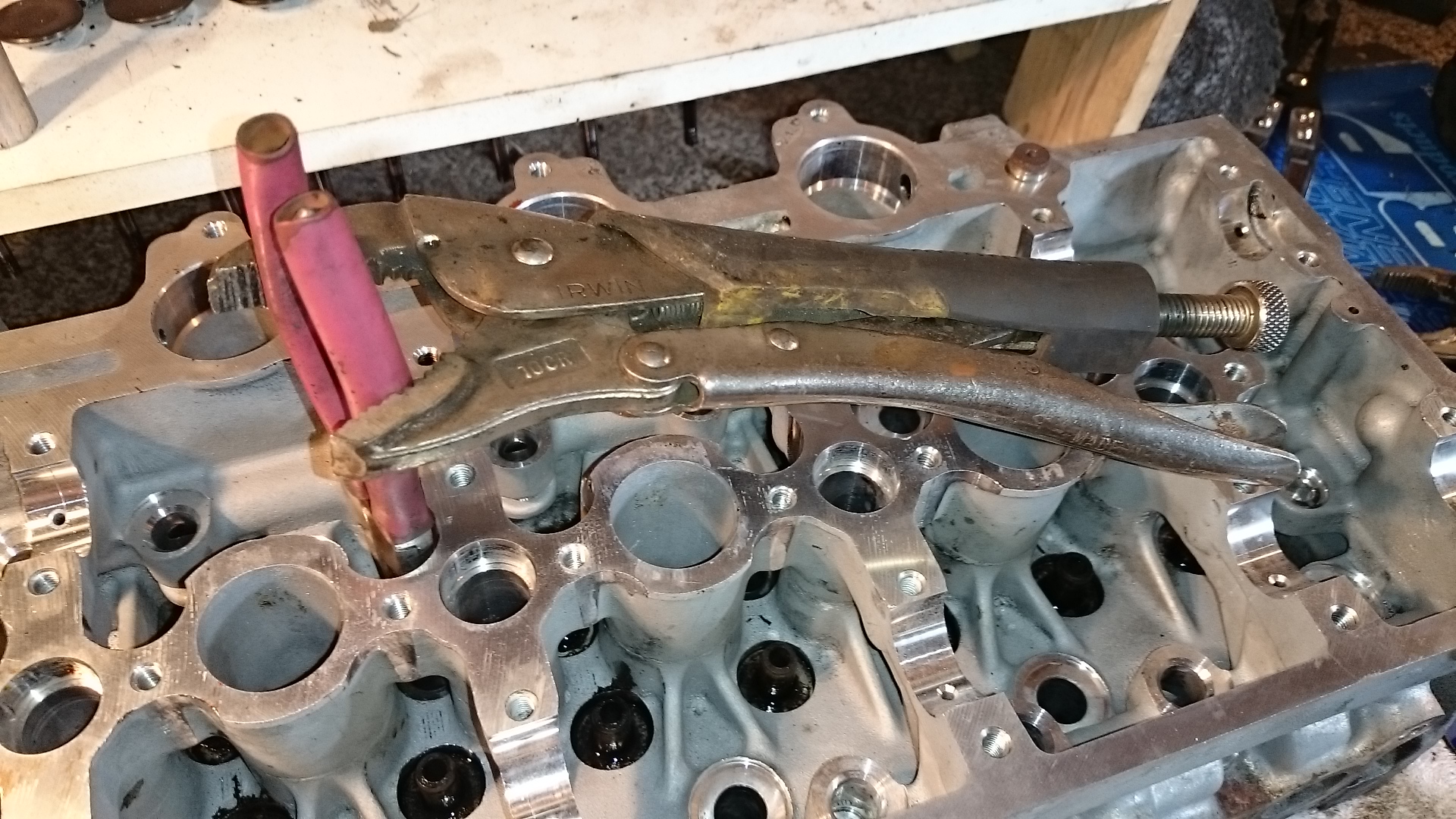

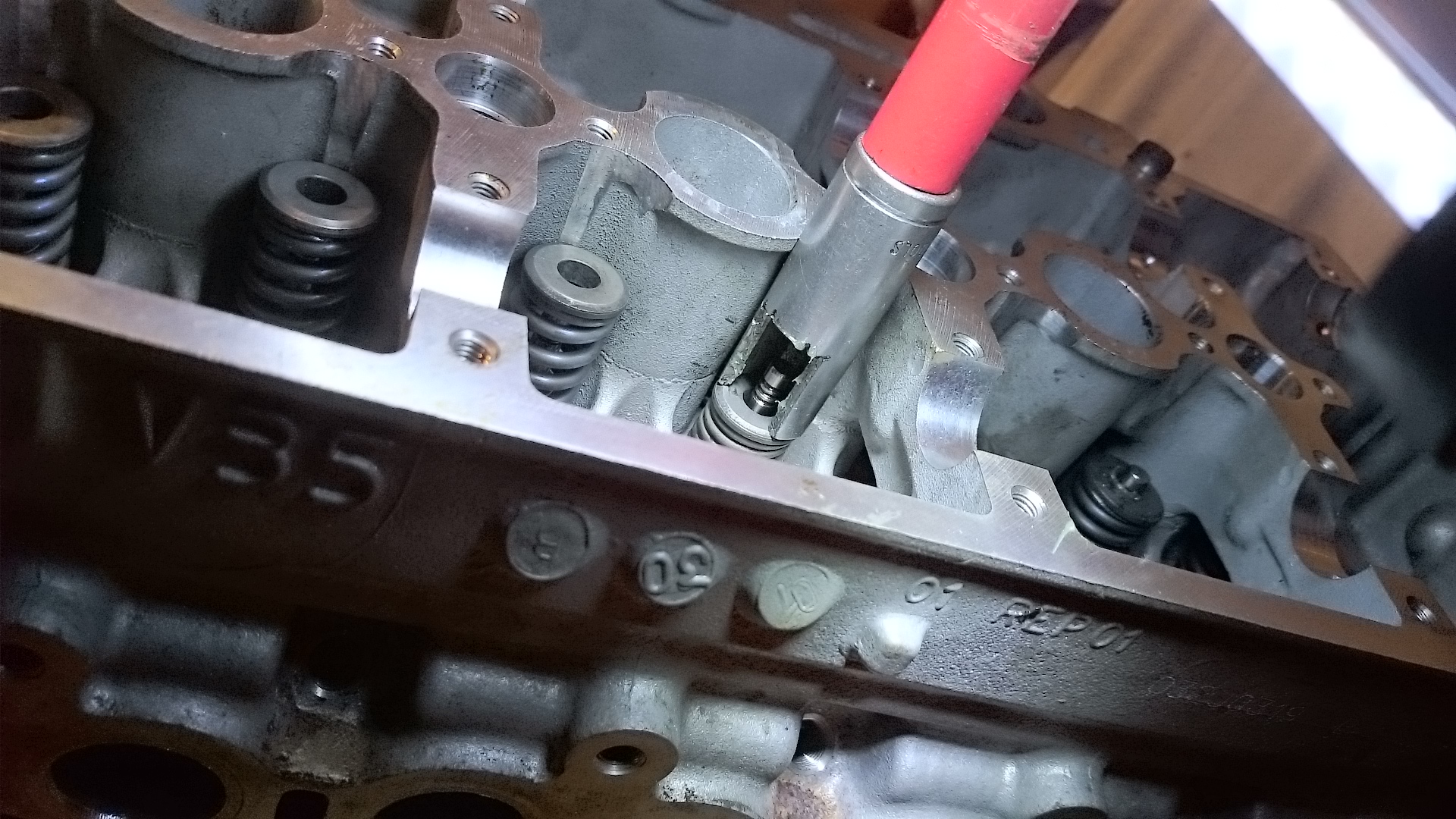

Made up a "specialist tool" for the stem seals as they are a total utter cows udder.

Also drilled and tapped the end hole for the swirl flap shaft. Made a bolt to fit. Sealed her in gurrrd

Posts: 15,646

Threads: 541

Joined: Dec 2011

Reputation:

124

Location: Aylesbury

Car Model/Spec: 320bhp Impreza WRX

Thanks: 7

Given 59 thank(s) in 58 post(s)

Love how Piggy spends the whole video talking about Boars.

Probably find it funnier than I should.

Posts: 20,092

Threads: 591

Joined: Nov 2012

Reputation:

54

Location: Cotswolds

Car Model/Spec: Stage 13 16v HDi

Thanks: 22

Given 68 thank(s) in 68 post(s)

(27-09-2016, 06:32 PM)Dum-Dum Wrote: Love how Piggy spends the whole video talking about Boars.

Probably find it funnier than I should.

Next video...

Oinking out the valve seals

Posts: 20,092

Threads: 591

Joined: Nov 2012

Reputation:

54

Location: Cotswolds

Car Model/Spec: Stage 13 16v HDi

Thanks: 22

Given 68 thank(s) in 68 post(s)

Posts: 20,092

Threads: 591

Joined: Nov 2012

Reputation:

54

Location: Cotswolds

Car Model/Spec: Stage 13 16v HDi

Thanks: 22

Given 68 thank(s) in 68 post(s)

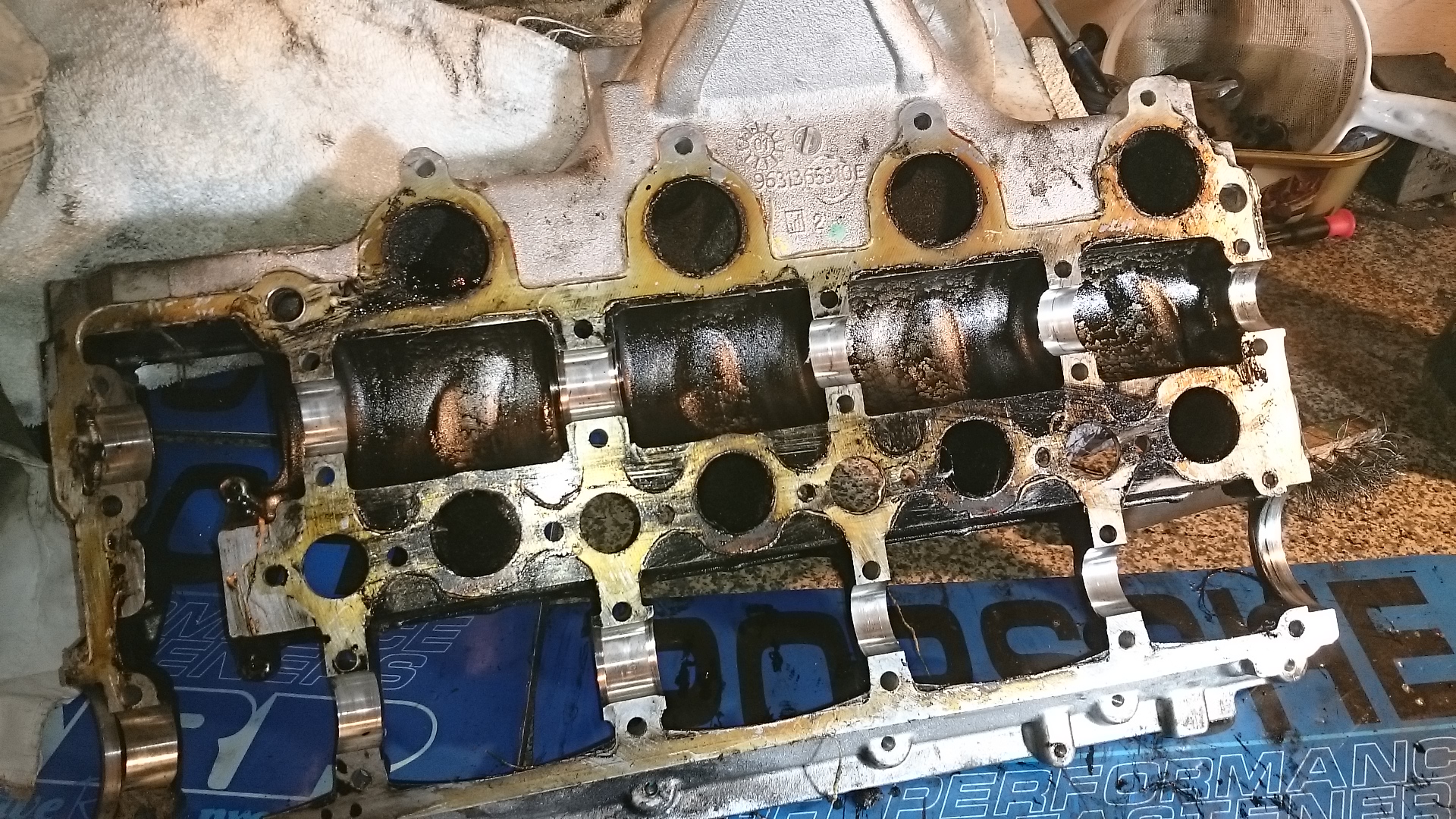

Finished the SIXTEEN valve seats this evening...exhaust side were AWFUL!

Also... painted a gearbox

Wow. What a day.

Posts: 391

Threads: 29

Joined: Sep 2014

Reputation:

0

Thanks: 1

Given 7 thank(s) in 7 post(s)

Looking good, long before some one starts doing 16v HDI conversion kits?

Painting cast aluminium is a pet hate of mine though!!!!

Posts: 20,092

Threads: 591

Joined: Nov 2012

Reputation:

54

Location: Cotswolds

Car Model/Spec: Stage 13 16v HDi

Thanks: 22

Given 68 thank(s) in 68 post(s)

(10-10-2016, 07:50 AM)allye Wrote: Looking good, long before some one starts doing 16v HDI conversion kits?

Painting cast aluminium is a pet hate of mine though!!!!

Kit is something like....

Find a 16v hdi. Fit the head and injectors to your 8v.

Posts: 3,539

Threads: 42

Joined: Mar 2012

Reputation:

28

Thanks: 3

Given 89 thank(s) in 88 post(s)

Posts: 20,092

Threads: 591

Joined: Nov 2012

Reputation:

54

Location: Cotswolds

Car Model/Spec: Stage 13 16v HDi

Thanks: 22

Given 68 thank(s) in 68 post(s)

(10-10-2016, 10:24 AM)welshpug Wrote: not pistons too?

There is a theory no...but i forgot to test them before i chucked the 8v ones

Posts: 1,778

Threads: 213

Joined: Jul 2013

Reputation:

2

Location: The North

Car Model/Spec: HDI

Thanks: 52

Given 16 thank(s) in 16 post(s)

Sound easy enough swapping the head/injectors over from the 16v to the HDI 90, but wouldnt you then have to get it remapped properly by someone who knew exactly what they were doing (think its only pro steve that can do this sort of mapping)? Plus unless you were going for big power on the HDI 90 it wouldnt really be that neccessary would it as the inejctors are good for a good amount of power anyway?

Posts: 3,662

Threads: 127

Joined: Feb 2012

Reputation:

33

Location: London

Car Model/Spec: ZX Volcane TD

Thanks: 6

Given 31 thank(s) in 31 post(s)

(10-10-2016, 03:20 PM)MY95 Wrote: Sound easy enough swapping the head/injectors over from the 16v to the HDI 90, but wouldnt you then have to get it remapped properly by someone who knew exactly what they were doing (think its only pro steve that can do this sort of mapping)? Plus unless you were going for big power on the HDI 90 it wouldnt really be that neccessary would it as the inejctors are good for a good amount of power anyway?

I would think you could run stock management on a stock map and still see 136bhp - someone correct me if im wrong.

The potential for big power with the 16v head is huge, it flows exceptionally well.

Its a case of build it and they will come (and map it) - should see over 200bhp with ease and more beyond.

8v hdi rarely sees 180+ even with $$$ spending on it.

I for one am watching these builds with a keen interest.

Posts: 20,092

Threads: 591

Joined: Nov 2012

Reputation:

54

Location: Cotswolds

Car Model/Spec: Stage 13 16v HDi

Thanks: 22

Given 68 thank(s) in 68 post(s)

No, will need remapping to suit.

Posts: 391

Threads: 29

Joined: Sep 2014

Reputation:

0

Thanks: 1

Given 7 thank(s) in 7 post(s)

So when HDI tuning has a off the shelf map for the 16v setup mentioned above on a 8v ecu that will make things very easy.

Posts: 20,092

Threads: 591

Joined: Nov 2012

Reputation:

54

Location: Cotswolds

Car Model/Spec: Stage 13 16v HDi

Thanks: 22

Given 68 thank(s) in 68 post(s)

(10-10-2016, 06:55 PM)allye Wrote: So when HDI tuning has a off the shelf map for the 16v setup mentioned above on a 8v ecu that will make things very easy.

Hmmm. It wont be quite an "off the shelf" as the turbo you choose, boost control, injector and fuel pump choice, clutch etc will all alter map requirements.

Posts: 5,205

Threads: 91

Joined: Dec 2011

Reputation:

83

Location: Oxfordshire/Cornwall

Car Model/Spec: Moonstone DT/Volvo V50

Thanks: 2

Given 41 thank(s) in 41 post(s)

2.0/2.2 16v/8v Bosch ECUs are (for our purposes) identical in terms of hardware, it's only the software that changes.

The Bosch managed 2.0 16v engines (RHW/RHM/RHT) are 110hp, infact the injectors are ever so slightly smaller in the 2.0 16v injectors than the 2.0 8v - you just have to use the 2.2 16v injectors, which are a reasonable upgrade, not to mention, upgraded nozzles are significantly easier for the 16v engines.

I'd suspect if you put a set of RHW/RHM/RHT injectors in and stock everything else, with a 16v head, it would almost certainly run and start without problems, by no means would it be optimal, there's a lot that would need changing and recalibrating to make it run it's best, but essentially - all the information that you need to remap one to suit is available since you're using OEM parts. Whoever remaps it just needs to know what needs changing to make it run correctly, be a bit of trial and error, but it's certainly been done before!

(16-05-2016, 10:45 AM)Toms306 Wrote: Oh I don't care about the stripped threads lol, that's easily solved by hammering the bolt in.  Nanstone GTD5 GT17S - XUD9TE

Volvo V50 D5 R-Design SE Sport - Daily cruise wagon.

Posts: 3,419

Threads: 120

Joined: Jan 2014

Reputation:

35

Location: Powys / Herefordshire

Car Model/Spec: Rallye/S16 & 175 megane

Thanks: 147

Given 40 thank(s) in 40 post(s)

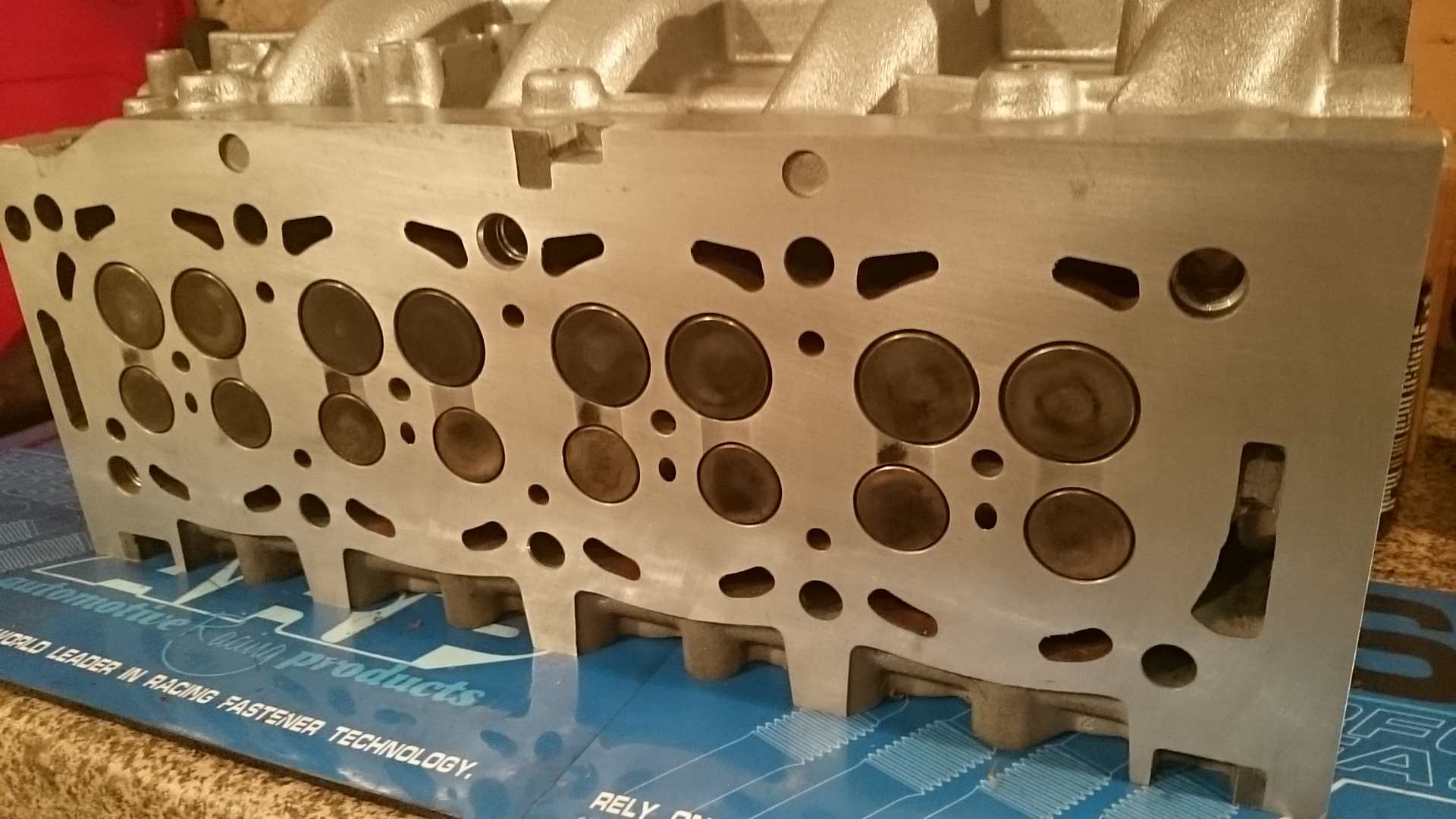

Hmm had a 2.0 16v RHR engine come in earlier...

![[Image: 17b33c2a-8471-4313-992e-0a4b324cf926_zps2e63812a.jpg]](http://i143.photobucket.com/albums/r143/matt-taylor/17b33c2a-8471-4313-992e-0a4b324cf926_zps2e63812a.jpg)

Team Cyril

Posts: 5,205

Threads: 91

Joined: Dec 2011

Reputation:

83

Location: Oxfordshire/Cornwall

Car Model/Spec: Moonstone DT/Volvo V50

Thanks: 2

Given 41 thank(s) in 41 post(s)

RHR is quite different, you'll notice uses a Siemens CR pump on the side of the head etc. Combustion chambers in pistons are quite different etc so Bosch 2.0/2.2 injectors cannot be used (1.6HDi ones are actually the closest...), no crank sensor on flywheel, rather under the crank pulley like on the 1.6HDi. Unless you're intending on doing quite a "hybrid"y build - fairly useless to 306 owners

(16-05-2016, 10:45 AM)Toms306 Wrote: Oh I don't care about the stripped threads lol, that's easily solved by hammering the bolt in.  Nanstone GTD5 GT17S - XUD9TE

Volvo V50 D5 R-Design SE Sport - Daily cruise wagon.

Posts: 20,092

Threads: 591

Joined: Nov 2012

Reputation:

54

Location: Cotswolds

Car Model/Spec: Stage 13 16v HDi

Thanks: 22

Given 68 thank(s) in 68 post(s)

Big parcel arrived today...

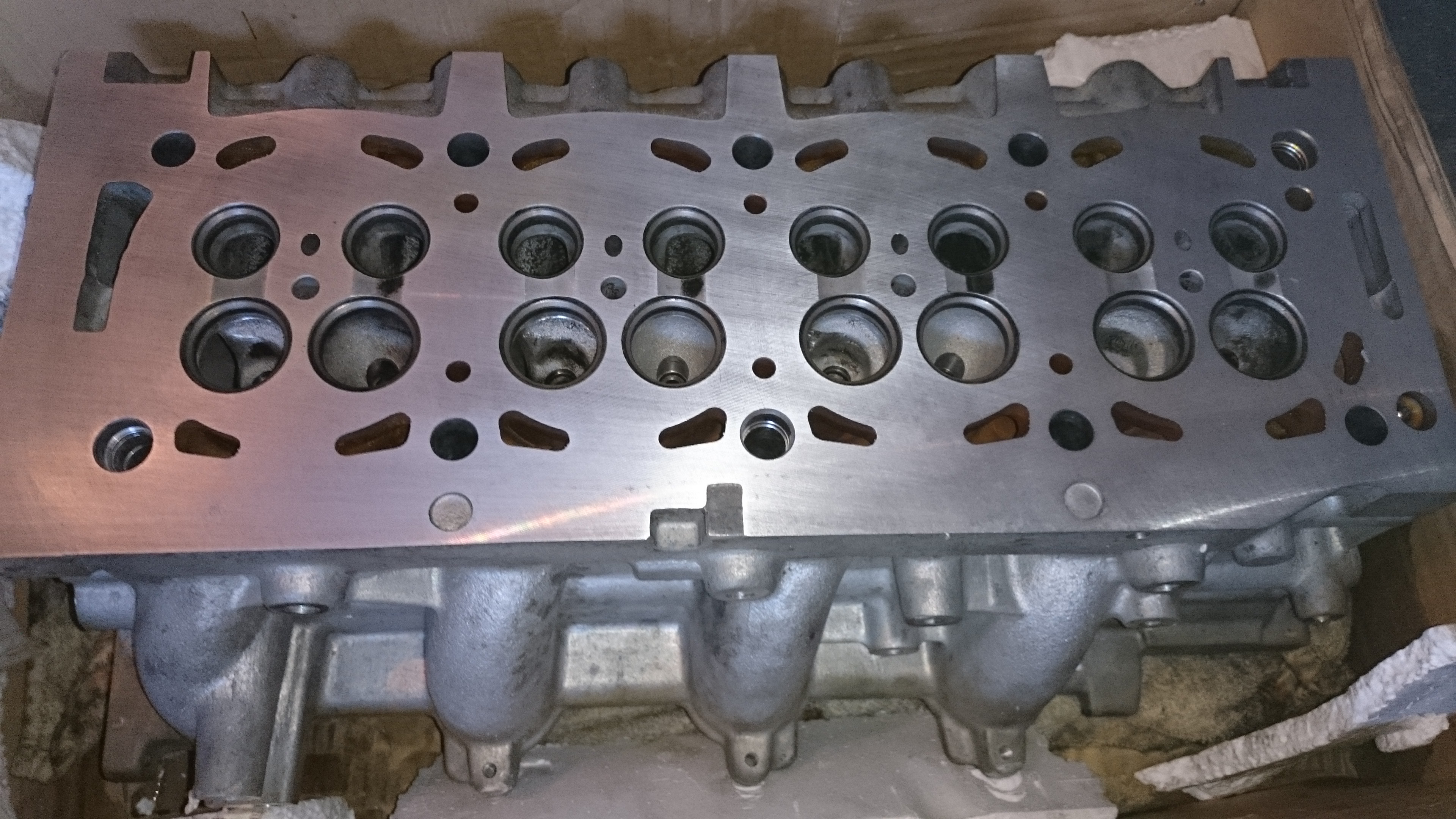

Head back from engineers and flangey time.

Also pictured are a load of the aux bits which were cleaned up and painted...quite time consuming and boring...actually, VERY time consuming and mind numbingly boring.

This weekend...things happen.

Posts: 20,092

Threads: 591

Joined: Nov 2012

Reputation:

54

Location: Cotswolds

Car Model/Spec: Stage 13 16v HDi

Thanks: 22

Given 68 thank(s) in 68 post(s)

15-10-2016, 06:20 PM

(This post was last modified: 16-10-2016, 06:00 AM by Piggy.)

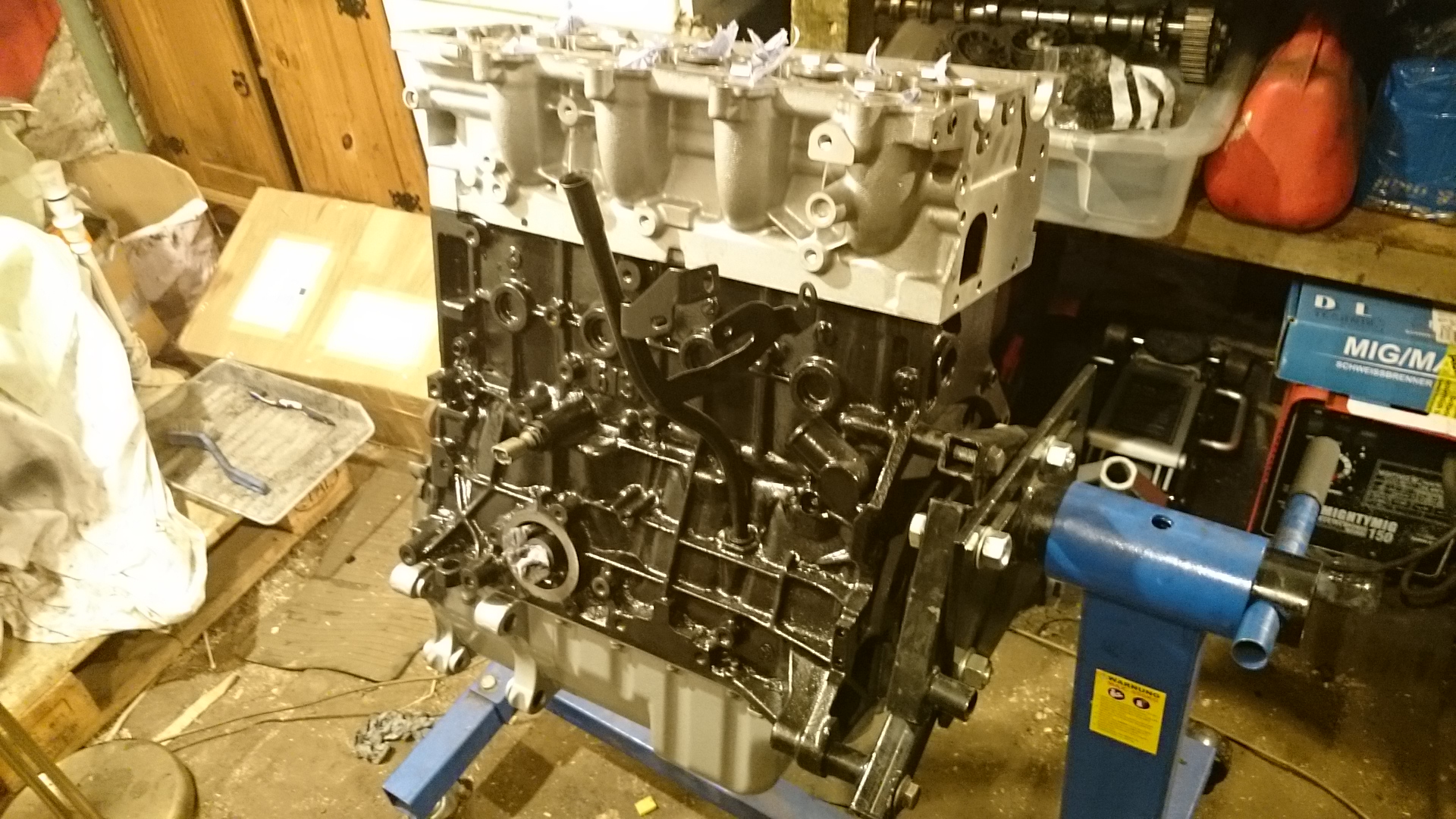

Managed to get an hour on this today ..went from empy weekend to driveway of Pugs to fix...

Had to spend sometime this week cleaning this...what a mess it was...90% blocked in places...

Anyways...good things happened!

First... Valve springs. Left one is old 45lb, right hand is uprated 75lb.

Fitting them...can't use ordinary spring compressor for many reasons...so...

Then I shoved a Elring HG on the deck and wacked a rather useful 16v head on it!

Wet pants moment when bad noises were heard as i torqued the head down with the ARPs...

Slight relief met with annoyance when I then snapped the 12 sided socket on the next nut...

Que a lot of rumaging to find another!

Posts: 15,646

Threads: 541

Joined: Dec 2011

Reputation:

124

Location: Aylesbury

Car Model/Spec: 320bhp Impreza WRX

Thanks: 7

Given 59 thank(s) in 58 post(s)

Posts: 20,092

Threads: 591

Joined: Nov 2012

Reputation:

54

Location: Cotswolds

Car Model/Spec: Stage 13 16v HDi

Thanks: 22

Given 68 thank(s) in 68 post(s)

16-10-2016, 06:00 AM

(This post was last modified: 16-10-2016, 06:01 AM by Piggy.)

(15-10-2016, 08:38 PM)Dum-Dum Wrote: 6 sided FTW

ARP nuts are 12 sided. (12 point)

Posts: 20,092

Threads: 591

Joined: Nov 2012

Reputation:

54

Location: Cotswolds

Car Model/Spec: Stage 13 16v HDi

Thanks: 22

Given 68 thank(s) in 68 post(s)

Started bolting bits up ....seeing how/if stuff fits. Feeling the 12month gap since strip down when i have boxes of random bolts

Aux stuff seems ok but the engine mount block wont fit. Need a 16v one it seems.

However this means 15degree not 30degree...so not 100% sure what to do there yet. Plenty to do in meantime.

Couple good lads are trying to find bits/remember...but open to anyone who has solved this

Posts: 1,417

Threads: 34

Joined: Dec 2011

Reputation:

8

Thanks: 0

Given 7 thank(s) in 7 post(s)

(16-10-2016, 06:00 AM)Piggy Wrote: (15-10-2016, 08:38 PM)Dum-Dum Wrote: 6 sided FTW

ARP nuts are 12 sided. (12 point) Could sworn your previous post said 16 sided.. Sneaky edit to 12 sided? Lol

Sent from my LG-H850 using Tapatalk

Posts: 20,092

Threads: 591

Joined: Nov 2012

Reputation:

54

Location: Cotswolds

Car Model/Spec: Stage 13 16v HDi

Thanks: 22

Given 68 thank(s) in 68 post(s)

In the words of Die Antwoord...

"I am a ninja,...yo."

Posts: 3,662

Threads: 127

Joined: Feb 2012

Reputation:

33

Location: London

Car Model/Spec: ZX Volcane TD

Thanks: 6

Given 31 thank(s) in 31 post(s)

(17-10-2016, 05:19 AM)Piggy Wrote: In the words of Die Antwoord...

"I am a ninja,...yo."

totally zef

Posts: 15,646

Threads: 541

Joined: Dec 2011

Reputation:

124

Location: Aylesbury

Car Model/Spec: 320bhp Impreza WRX

Thanks: 7

Given 59 thank(s) in 58 post(s)

Never expected Piggy to know Die Antwoord lyrics.

Posts: 1,791

Threads: 19

Joined: Jun 2012

Reputation:

12

Location: Devonshire

Car Model/Spec: Peugeot 309 GRD(T)

Thanks: 4

Given 25 thank(s) in 24 post(s)

17-10-2016, 08:18 AM

(This post was last modified: 17-10-2016, 08:19 AM by mr_fish.)

Impressed with the valve compressor

(16-10-2016, 07:44 PM)Piggy Wrote: Started bolting bits up ....seeing how/if stuff fits. Feeling the 12month gap since strip down when i have boxes of random bolts

Aux stuff seems ok but the engine mount block wont fit. Need a 16v one it seems.

However this means 15degree not 30degree...so not 100% sure what to do there yet. Plenty to do in meantime.

Couple good lads are trying to find bits/remember...but open to anyone who has solved this

Top engine mount wont decide your 15/30* issue, the gearbox does that.

Presume you'll be using a standard 306 DT/HDi box? So you'll just have it in the stock 306 30* position

Engine mount off a 8v won't work (as you've discovered) will need one off a 807 or something with the bosch managed 16v HDi

You'll then discover the 306 chassis to engine mount part wont fit, so then that'll need 'adjustment'

Your basically doing the same as darren the first time round he fitted his valver engine

Posts: 20,092

Threads: 591

Joined: Nov 2012

Reputation:

54

Location: Cotswolds

Car Model/Spec: Stage 13 16v HDi

Thanks: 22

Given 68 thank(s) in 68 post(s)

17-10-2016, 11:50 AM

(This post was last modified: 17-10-2016, 11:53 AM by Piggy.)

What adjustement we talking? Im considering just "adjusting" the engine part, ie drilling two new holes

And surely the engine top mount does affect the 15/30 degrees... Cant see how it wouldnt. Obviously gearbox does too...but the top of the block mount is a "level" surface...so if you used a 15degree gearbox...need to match engine mount and visa versa?

Posts: 4,604

Threads: 90

Joined: Dec 2011

Reputation:

54

Location: Cornwall

Car Model/Spec: 1996 306 DT M-TDI/16

Thanks: 0

Given 20 thank(s) in 18 post(s)

The mount is also angled differently between 15 / 30 degree engines, but yes, the offset bell housing is where the major difference is between BE3 and 4 transmission housings.

| Dyno Power Runs & Steady State Facilities Available, Just Ask Anytime |

| #DervMafia |

![[Image: sigi-2.png]](http://i281.photobucket.com/albums/kk226/darrenjlobb/sigi-2.png)

Posts: 1,791

Threads: 19

Joined: Jun 2012

Reputation:

12

Location: Devonshire

Car Model/Spec: Peugeot 309 GRD(T)

Thanks: 4

Given 25 thank(s) in 24 post(s)

Yeah making the holes bigger/re-drill, just to line up. It wasn't going to work for me so I didn't look into it too much.

Gearbox makes most of the difference then. Top engine mount being rubber will take up the rest of how the engine wants to sit.

|

![[Image: 17b33c2a-8471-4313-992e-0a4b324cf926_zps2e63812a.jpg]](http://i143.photobucket.com/albums/r143/matt-taylor/17b33c2a-8471-4313-992e-0a4b324cf926_zps2e63812a.jpg)

![[Image: sigi-2.png]](http://i281.photobucket.com/albums/kk226/darrenjlobb/sigi-2.png)