02-05-2016, 06:43 PM

So I tried the 'ignore it and it'll go away' solution but the fairys didnt come and fit my engine so i had to resort to the 'its bank holiday and ive finally got a day off' solution.

I had been waiting for parts for awhile, that and fine weather to finish the top boost pipe.

All put together the top pipe using norman constant tension clamps

I'd ordered some nipples for the boost guage take off but the bugger snapped before it was even down tight, so uncovered the lathe and made a new one from an old mig tip .

Swapped the rear mounts out and dropped the engine in the bay.

Managed to get all the loom and and rear coolant pipes plumbed before the rain stopped play.

I swiftly retreated the the garage to make a holder for the fuel filter i found in the garage,

Que a buggered conrod and many jokes about keeping a spare for the engine

Ill update the rest once the paint dry's on the new mount

I had been waiting for parts for awhile, that and fine weather to finish the top boost pipe.

All put together the top pipe using norman constant tension clamps

I'd ordered some nipples for the boost guage take off but the bugger snapped before it was even down tight, so uncovered the lathe and made a new one from an old mig tip .

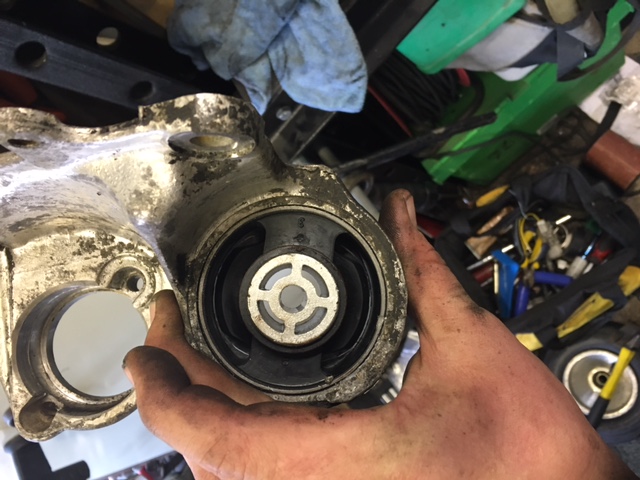

Swapped the rear mounts out and dropped the engine in the bay.

Managed to get all the loom and and rear coolant pipes plumbed before the rain stopped play.

I swiftly retreated the the garage to make a holder for the fuel filter i found in the garage,

Que a buggered conrod and many jokes about keeping a spare for the engine

Ill update the rest once the paint dry's on the new mount

proper good idea that is haha

proper good idea that is haha

A hell of alot has happened since the last update.

A hell of alot has happened since the last update.

Once the snacks and brew was devoured I jacked her up to find two very dead P bushes, how this happened is beyond both me and Frav as she was fine going to the test and Frav wouldve never passed her like this, the only thing we could think of at the time was he'd just had a brand new stand alone test lane installed which may of possibly helped accelerate the failure???

Once the snacks and brew was devoured I jacked her up to find two very dead P bushes, how this happened is beyond both me and Frav as she was fine going to the test and Frav wouldve never passed her like this, the only thing we could think of at the time was he'd just had a brand new stand alone test lane installed which may of possibly helped accelerate the failure???